What Makes Mid Drive Electric Motors Superior Mid drive electric motors mount at the bicycle's bottom bracket and directly power the crankshaft, delivering 40-60% better hill-climbing performance and 15-20% greater range compared to hub motors. This central positioning creates optimal weight distri...

READ MOREHigh reliability and good compatibility VCU (including TBOX)

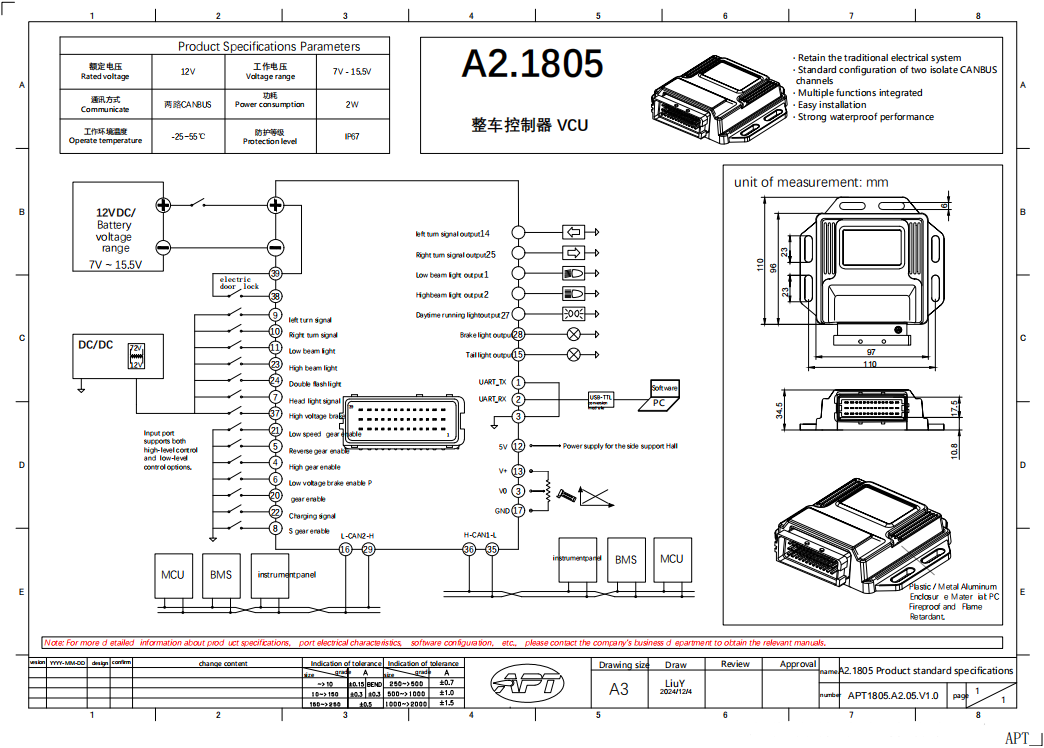

In the APT permanent magnet motor drive system, the vehicle control unit (VCU) serves as the core of the entire vehicle control system. Through deep collaboration with the motor controller (MCU) and the battery management system (BMS), the VCU provides systematic advantages for the efficient and safe operation of the permanent magnet motor. The following are the key advantages and technical details of the VCU in the permanent magnet motor drive.

Technical Parameters

Application&Features

Contact us

I. Dynamic torque optimization and precise control

The VCU, through the high-speed CAN bus, collects signals from the accelerator pedal and brake pedal in real time, and combines vehicle status (such as speed, battery SOC, motor temperature) to perform dynamic torque distribution. For example, in the acceleration condition, the VCU generates a target torque command based on the pedal opening and the battery discharge capacity, and optimizes the motor output through PID algorithms or sliding mode control strategies (such as direct torque control based on sliding mode control, SMC-DTC) to reduce torque pulsation and magnetic flux fluctuations, and improve driving smoothness. For the dual-motor four-wheel drive architecture, the VCU can dynamically adjust the torque ratio between the front and rear axles (such as reducing the torque of the slipping axle on wet roads) to improve handling stability.

Regenerative braking energy recovery. During braking, the VCU collaborates with the MCU to control the motor to enter the power generation state, converting kinetic energy into electrical energy and feeding it back to the battery. By real-time monitoring of battery SOC, temperature, and brake pedal depth, the VCU dynamically adjusts the upper limit of regenerative braking torque to ensure maximum energy recovery efficiency (typically increasing the range by 10%-15%) while avoiding battery overload. For example, when the battery SOC is above 95% or the vehicle speed is below 10 km/h, the VCU automatically disables regenerative braking and switches to traditional friction braking.

Multi-mode drive strategy. The VCU supports various driving modes such as economy (ECO), sport (SPORT), and snow (SNOW), adjusting torque output characteristics and energy management strategies to meet different scenarios. For example, in the ECO mode, the VCU reduces the torque variation rate and limits the maximum feedback torque (such as - 100 Nm), while in the SPORT mode, it enhances response speed and relaxes torque restrictions.

II. System-level energy efficiency optimization and reliability

Through real-time communication with the BMS, it dynamically optimizes the matching of battery output power and motor load. For example, during climbing or high-speed driving, the VCU prioritizes the use of high-power output from the battery; during low-speed cruising, it switches to the high-efficiency operating range of the motor to reduce overall energy consumption.

Wide temperature range and anti-interference capability. To meet the high reliability requirements of the permanent magnet motor in complex working conditions, the VCU hardware design typically operates within a wide temperature range of - 40°C to 125°C and employs multi-layer PCB layout, differential signal transmission, and TVS surge protection measures to reduce the impact of electromagnetic interference (EMI) on motor control.

III. Intelligent Integration and Technological Expandability

Multi-domain integration and centralized architecture,

As the vehicle's electronic and electrical architecture evolves towards centralization, the VCU is gradually integrating functions from the power domain and chassis domain, reducing the number of ECUs.

Standardized communication and compatibility:

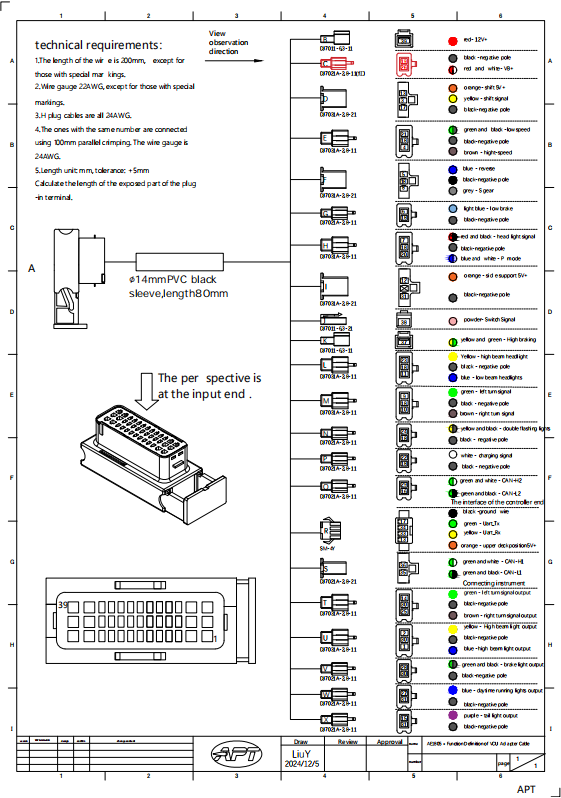

The VCU conducts high-speed data interaction with MCUs, BMSs, and external devices (such as charging stations) via protocols such as CANBUS. For example, during charging, the VCU negotiates charging power with the charging station and real-time monitors the battery status to ensure charging safety. At the same time, the VCU supports standard diagnostic protocol, allowing for fault code reading and parameter calibration through on-board diagnostic tools, reducing development and maintenance costs.

|

|

- Individual buyers

- Corporate Procurement

By pressing the "Send" button, you confirm that you give the company your consent for processing your personal data.

High reliability and good compatibility VCU (including TBOX) Suppliers

Building on its long-accumulated core motor drive technologies and unique experience in high-power MOSFET parallel connection, Shanghai APT Power Technology Co., Ltd. focuses on providing high-end customers in the industry with core hardware, embedded software for motor drive products, and supporting technical services. High reliability and good compatibility VCU (including TBOX) Suppliers in China. Guided by the business philosophy of enhancing the core value of end products, it lays out long-term development strategies to assist customers in their brand growth initiatives.

Over the years, the company has continuously launched high-performance drive control products across various voltage levels, covering application scenarios such as electric motorcycles, electric robot chassis, electric ATVs, UTVs, and electric outboard motors. Wholesale High reliability and good compatibility VCU (including TBOX) Factory. Leveraging mature and reliable product applications, it adheres to better technical solutions and high-quality hardware materials, expanding the market reputation of major complete machine manufacturers by improving user experience.

In the future, the company will continue to deepen its expertise in motor drive technology and focus on fields requiring high quality and reliability. It is committed to becoming a brand benchmark in the motor drive niche industry and creating greater value for various outstanding brands in the new energy power track.

-

-

Mid-drive electric motors—mounted at the bicycle’s bottom bracket, where pedals attach—deliver superior power transfer, hill-climbing ability, and ride balance compared to hub motors, making them the preferred choice for performance e-bikes, cargo bikes, and off-road models. By leveraging the bike’...

READ MORE -

Motor controllers are an essential component in many systems, enabling the precise control of motor performance. As industries advance, the role of software in motor management has become increasingly critical. This article explores the intersection of hardware and software in modern motor controlle...

READ MORE

English

English Español

Español عربى

عربى