What Makes Mid Drive Electric Motors Superior Mid drive electric motors mount at the bicycle's bottom bracket and directly power the crankshaft, delivering 40-60% better hill-climbing performance and 15-20% greater range compared to hub motors. This central positioning creates optimal weight distri...

READ MOREMid-drive Motor

B To C business:

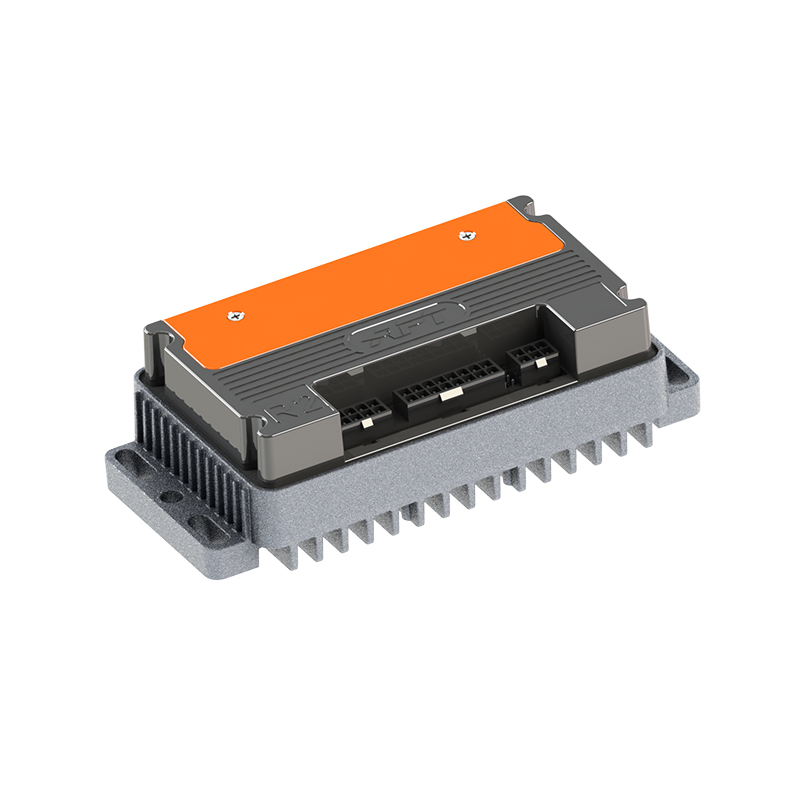

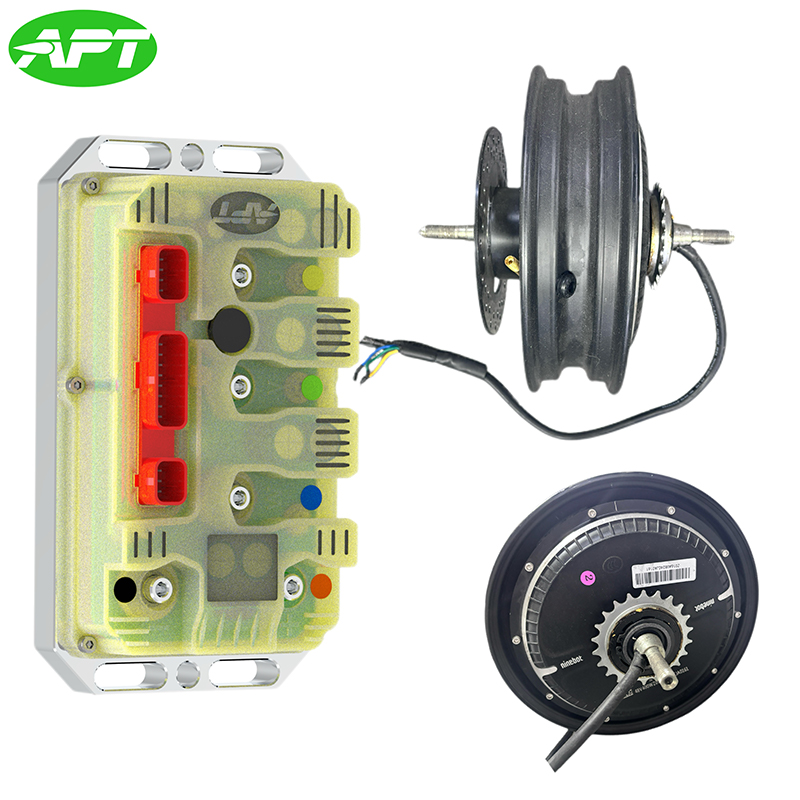

The B2C mid-mounted motor is a core power component designed for end consumers, focusing on high-end personal transportation and light vehicle scenarios. Its core applications include high-end electric bicycles (such as mountain-terrain models, long-distance commuting models), camping trailers, small assistive trolleys, and other multi-functional vehicles. APT meets users' advanced demands for power and control; some models also integrate sensors to achieve intelligent power assistance adjustment, and are equipped with overcurrent, overvoltage, and overheat protection functions, balancing experience and safety.

Technical Parameters

Application&Features

Contact us

| BtoC Product Pairing | ||

|

|

|

|

||

|

|

|

|

|

- Individual buyers

- Corporate Procurement

By pressing the "Send" button, you confirm that you give the company your consent for processing your personal data.

Electric Bicycle Mid Drive Motors Manufacturers

Building on its long-accumulated core motor drive technologies and unique experience in high-power MOSFET parallel connection, Shanghai APT Power Technology Co., Ltd. focuses on providing high-end customers in the industry with core hardware, embedded software for motor drive products, and supporting technical services. Electric Bicycle Mid Drive Motors Manufacturers in China. Guided by the business philosophy of enhancing the core value of end products, it lays out long-term development strategies to assist customers in their brand growth initiatives.

Over the years, the company has continuously launched high-performance drive control products across various voltage levels, covering application scenarios such as electric motorcycles, electric robot chassis, electric ATVs, UTVs, and electric outboard motors. Custom Bike Mid Drive Motors Factory. Leveraging mature and reliable product applications, it adheres to better technical solutions and high-quality hardware materials, expanding the market reputation of major complete machine manufacturers by improving user experience.

In the future, the company will continue to deepen its expertise in motor drive technology and focus on fields requiring high quality and reliability. It is committed to becoming a brand benchmark in the motor drive niche industry and creating greater value for various outstanding brands in the new energy power track.

-

-

Mid-drive electric motors—mounted at the bicycle’s bottom bracket, where pedals attach—deliver superior power transfer, hill-climbing ability, and ride balance compared to hub motors, making them the preferred choice for performance e-bikes, cargo bikes, and off-road models. By leveraging the bike’...

READ MORE -

Motor controllers are an essential component in many systems, enabling the precise control of motor performance. As industries advance, the role of software in motor management has become increasingly critical. This article explores the intersection of hardware and software in modern motor controlle...

READ MORE

Industry knowledge

Electric Bicycle Mid Drive Motors: Performance and Efficiency

Electric bicycle mid drive motors are becoming increasingly popular due to their efficiency and performance advantages. Shanghai APT Power Technology Co., Ltd., founded in 2010, has focused its efforts on providing cutting-edge drive control technologies for permanent magnet synchronous motors, including mid drive motors used in electric bikes. These motors are known for their ability to deliver smooth power transfer, making them ideal for various types of e-bikes. This section explores the unique benefits and performance aspects of mid drive motors for electric bicycles.

Key Advantages of Mid Drive Motors in Electric Bicycles

Bike Mid Drive Motors offer several benefits over other motor types, especially in terms of performance, weight distribution, and efficiency. These advantages make mid drive motors an attractive option for a variety of e-bike applications, including city commuting, mountain biking, and cargo transport. Some of the key benefits include:

- Efficient Power Transfer: Mid drive motors are integrated into the bike’s drivetrain, providing a direct transfer of power to the pedals. This results in improved overall efficiency, especially on steep hills or when varying the pedaling cadence.

- Better Handling and Balance: The central placement of mid drive motors helps balance the bike’s weight more evenly, improving its handling, stability, and control, particularly on challenging terrains or during tight maneuvers.

- Higher Torque at Lower Speeds: Mid drive motors excel in providing strong torque output at low speeds, making them ideal for mountain biking and off-road use where steep inclines or rough terrain require more power.

- Seamless Integration with Gears: The motor’s integration with the bike’s gears allows the rider to leverage the full torque potential by shifting gears, similar to a traditional pedal-powered bike, enhancing ride quality.

- Longer Range: Since mid drive motors work directly with the bike’s gears, they use the bike’s natural pedaling effort, improving energy efficiency and extending battery range, especially on long rides or tough routes.

Challenges in the Design and Maintenance of Mid Drive Motors

Although Mid-Drive Motors offer excellent performance, they also present challenges in design, durability, and maintenance. These challenges need to be addressed to maximize the longevity and functionality of the motor system. Some of the main challenges include:

- Wear and Tear on Gears: Since mid drive motors are directly connected to the bike’s drivetrain, they place additional stress on the gears, which can lead to faster wear and tear, especially in high-torque conditions.

- Increased Maintenance Requirements: The integration of the motor with the drivetrain means that more components are involved in power transmission, leading to a need for more frequent maintenance and monitoring of the bike's mechanical system.

- Cooling Needs: As mid drive motors often operate under heavy loads and high power demands, they require efficient cooling systems to prevent overheating, especially during extended or intensive use.

- Complexity in Integration: Integrating a mid drive motor with the bike’s electrical and mechanical systems requires a high level of design sophistication, making it more complex to manufacture and assemble compared to hub motors.

- Higher Cost: Due to their advanced design and integration with the bike’s gears, mid drive motors are often more expensive to produce and maintain compared to hub motors, making them a more costly option for consumers.

Advancements in Mid Drive Motor Technology

The technology behind mid drive motors is constantly evolving, with new innovations improving efficiency, performance, and ease of use. Some of the notable advancements include:

- Smart Motor Controllers: Modern mid drive motors are often equipped with smart controllers that adjust power output based on real-time data, such as terrain, rider input, and battery level, providing a smoother and more personalized riding experience.

- Improved Cooling Systems: New cooling technologies, such as liquid cooling and heat dissipation systems, are being incorporated into mid drive motors to manage heat buildup and enhance motor longevity.

- Energy Recovery Systems: Some mid drive motors now feature regenerative braking capabilities, allowing the motor to convert kinetic energy into electrical energy during braking, which is then stored in the battery for later use.

- Noise Reduction Technologies: Manufacturers are increasingly developing quieter mid drive motors by utilizing advanced components that reduce motor noise, making the riding experience more pleasant, especially in urban environments.

- Enhanced Torque Sensors: Advanced torque sensors are now integrated into mid drive systems to provide more responsive and precise control over the motor’s power output, resulting in better acceleration and a more natural riding feel.

Applications of Mid Drive Motors in E-Bikes

Mid drive motors are particularly well-suited for a wide variety of electric bike applications due to their performance and adaptability. Below are some of the most common applications:

Mountain Biking

Mid drive motors are an excellent choice for mountain bikes because they provide high torque and efficient power delivery on steep inclines, rocky trails, and other challenging terrains. The ability to shift gears in conjunction with the motor ensures a more controlled and dynamic riding experience in rough conditions.

Commuter and Urban Bikes

For urban commuting, mid drive motors provide consistent power delivery, especially when navigating hilly city streets or varied terrain. Their efficiency and lightweight design make them ideal for daily commutes, offering a smooth and energy-efficient ride.

Cargo Bikes

Mid drive motors are also commonly used in cargo bikes due to their ability to provide high torque and steady assistance when carrying heavy loads. The ability to adjust the power output depending on the load makes mid drive motors an essential choice for efficient and reliable cargo transport.

The Future of Mid Drive Motors in Electric Bicycles

As the demand for electric bicycles continues to rise, mid drive motor technology is expected to advance even further. Future developments may include:

- Increased Integration with Smart Technologies: The future of mid drive motors will see more integration with smart technologies, enabling riders to connect to their bikes via apps for performance tracking, diagnostics, and customizable settings.

- Advancements in Battery Management: Future mid drive systems will be optimized to work seamlessly with next-generation batteries, offering longer ranges and faster charging times, as well as better energy efficiency.

- Ultra-Lightweight Designs: As materials and manufacturing techniques evolve, mid drive motors are expected to become lighter and more compact, making them even more suitable for lightweight, high-performance e-bikes.

- Eco-Friendly Innovations: The next generation of mid drive motors may include more sustainable materials and environmentally friendly designs to further reduce the carbon footprint of electric bikes.

English

English Español

Español عربى

عربى