What Makes Mid Drive Electric Motors Superior Mid drive electric motors mount at the bicycle's bottom bracket and directly power the crankshaft, delivering 40-60% better hill-climbing performance and 15-20% greater range compared to hub motors. This central positioning creates optimal weight distri...

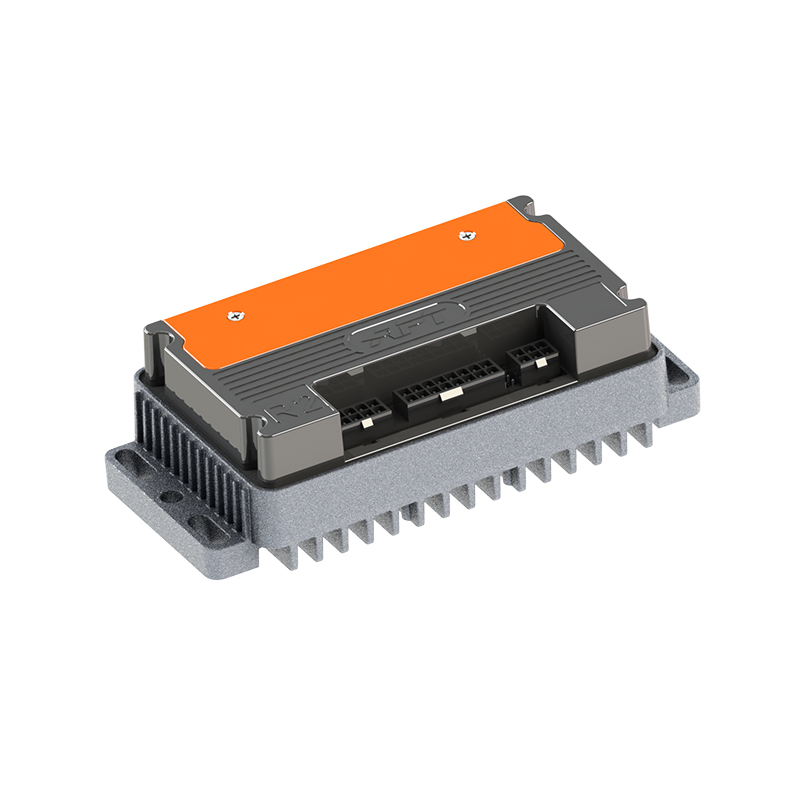

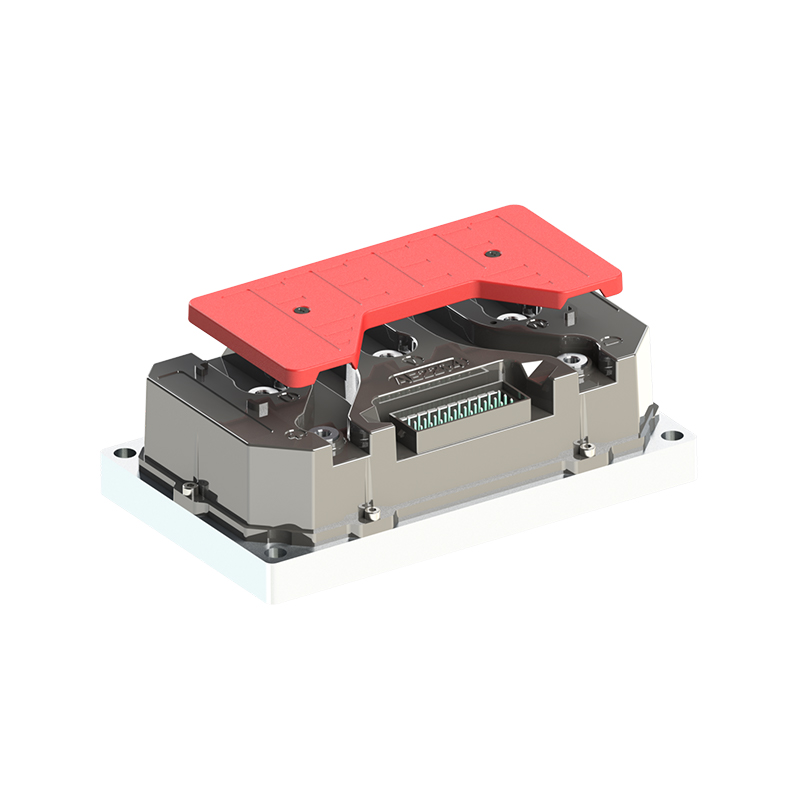

READ MORER2 High compatibility Brushless DC Motor Controller

The R2 2319 High Compatibility Brushless DC Motor Controller is designed to seamlessly integrate with a wide range of BLDC motors and systems, making it the go-to choice for versatile, plug-and-play performance. Featuring intelligent protection mechanisms—such as overvoltage, overcurrent, and thermal safeguards—the R2 2319 delivers reliable, stable operation in diverse environments. Its compact form factor and efficient power management enhance system responsiveness while minimizing energy loss.

APT-R2 Motor controller, Drive for a rated 2kW PMSM mid drive motor and BLDC Hub motor, Sinewave vector control technology special optimization for moped, scooter. Easily replace and upgrade other ordinary controllers.

Technical Parameters

Application&Features

Contact us

| Communication Interface | VCU Communication | CANBUS (Isolation type, default 120Ω terminal resistor) |

|

| Upper computer communication |

UART-TTL | ||

| Motor-related | Motor temperature sensing interface |

NTC/PTC((default parameters KTY83-122) | |

| Position signal avoidance |

Hall encoder or magnetic encoder | ||

| Motor-type | Permanent magnet synchronous motor, DC brushless motor |

||

| Equipment Support | Bluetooth or USB-TTL | ||

| Software Adaptation | APT eMotion | ||

| Executive standard | Electrical: GB/T18488 | Salt Spray: GB/T2423.17 | |

| IP Rating: GB/T4208-2017 | Vibration: GB/T2423.10-2008 | ||

| Input Rated Voltage | 30-170 | V | Power devices vary across different voltage platforms |

| Control Mode | Vector Control | - | FOC Sine Wave Modulation |

| Rated Power | 1.5-2 | KW | Hardware configuration adjustable |

| Peak Power | 2-4 | KW | Hardware configuration adjustable |

| Maximum DC Input Current | 150 | A.peak | Maximum withstand capacity of the DC bus |

| Rated Output Current | 100 | A.peak | Motor phase current (peak) |

| Maximum Output Current | 240 | A.peak | Motor phase current (peak) |

| Maximum Conversion Efficiency | 98% | - | - |

Orderable Specifications

|

Product |

Voltage |

Motor phase |

DC Input current |

|

|

Default limit |

Max. capability |

|||

|

R2.72S |

30-85V |

140A |

40A |

150A |

|

R2.72M |

30-85V |

180A |

50A |

150A |

|

R2.72L |

30-85V |

220A |

60A |

150A |

|

R2.96M |

30-118V |

150A |

40A |

150A |

Application Fields:

1. Pure electric and hybrid systems (traction or auxiliary):

• Road vehicle, utility vehicle, high-power electric motorcycle

• Off-road vehicles (tractors, bulldozers, special off-road vehicles, etc.)

• Electric boat, speedboat, and other fields of EV conversion

2. Design features:

The electrical system architecture is laid out in advance for automotive applications

Low voltage, high power, economical and efficient, very suitable for Off-road machinery

3. Technical features:

• Field-oriented vector control, in conjunction with APT-tuned algorithms, provides peak torque and optimal efficiency across the entire operating range

• Advanced Pulse Width Modulation technology provides efficient use of battery voltage, low motor harmonics, low torque ripple, and minimized switching losses

• Tunable to any BLDC or IPM motor. Fully programmable for optimal match to individual motor characteristics

• Field-Programmable, with FLASH downloadable main operating code

• Extremely wide torque/speed range, including full regeneration capability

• The unique software makes the system application easier than ever

• Benefit from the many decades of APT experience in the EV industry, quickly and simply decide your own proprietary PID parameter to differentiate your systems from your competition

- Individual buyers

- Corporate Procurement

By pressing the "Send" button, you confirm that you give the company your consent for processing your personal data.

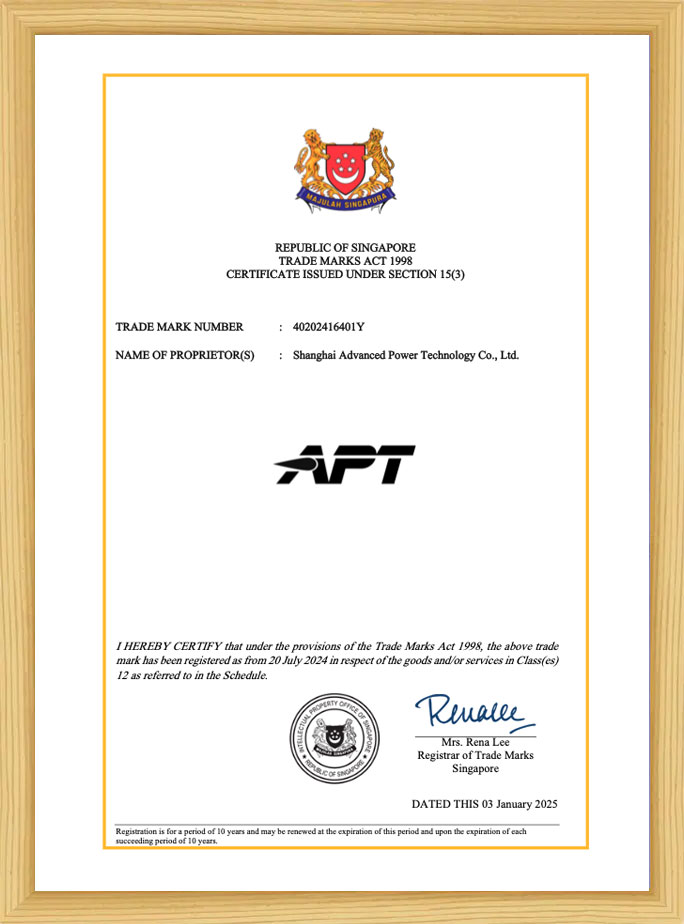

R2 High compatibility Brushless DC Motor Controller Suppliers

Building on its long-accumulated core motor drive technologies and unique experience in high-power MOSFET parallel connection, Shanghai APT Power Technology Co., Ltd. focuses on providing high-end customers in the industry with core hardware, embedded software for motor drive products, and supporting technical services. R2 High compatibility Brushless DC Motor Controller Suppliers in China. Guided by the business philosophy of enhancing the core value of end products, it lays out long-term development strategies to assist customers in their brand growth initiatives.

Over the years, the company has continuously launched high-performance drive control products across various voltage levels, covering application scenarios such as electric motorcycles, electric robot chassis, electric ATVs, UTVs, and electric outboard motors. Wholesale R2 High compatibility Brushless DC Motor Controller Factory. Leveraging mature and reliable product applications, it adheres to better technical solutions and high-quality hardware materials, expanding the market reputation of major complete machine manufacturers by improving user experience.

In the future, the company will continue to deepen its expertise in motor drive technology and focus on fields requiring high quality and reliability. It is committed to becoming a brand benchmark in the motor drive niche industry and creating greater value for various outstanding brands in the new energy power track.

-

-

Mid-drive electric motors—mounted at the bicycle’s bottom bracket, where pedals attach—deliver superior power transfer, hill-climbing ability, and ride balance compared to hub motors, making them the preferred choice for performance e-bikes, cargo bikes, and off-road models. By leveraging the bike’...

READ MORE -

Motor controllers are an essential component in many systems, enabling the precise control of motor performance. As industries advance, the role of software in motor management has become increasingly critical. This article explores the intersection of hardware and software in modern motor controlle...

READ MORE

English

English Español

Español عربى

عربى