Industry knowledge

Brushless DC Motor Controllers: Key Features and Advances

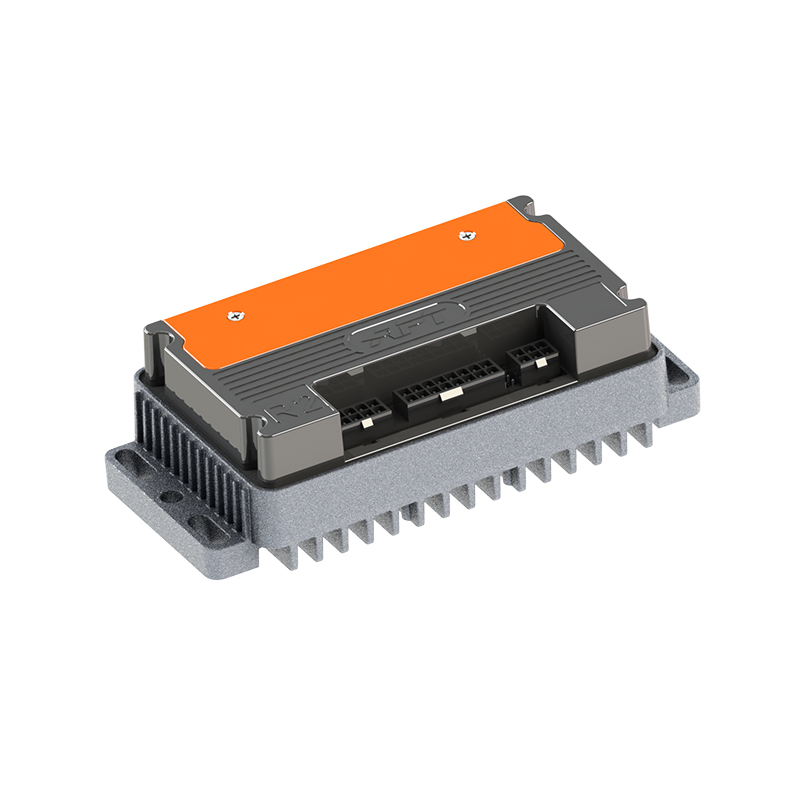

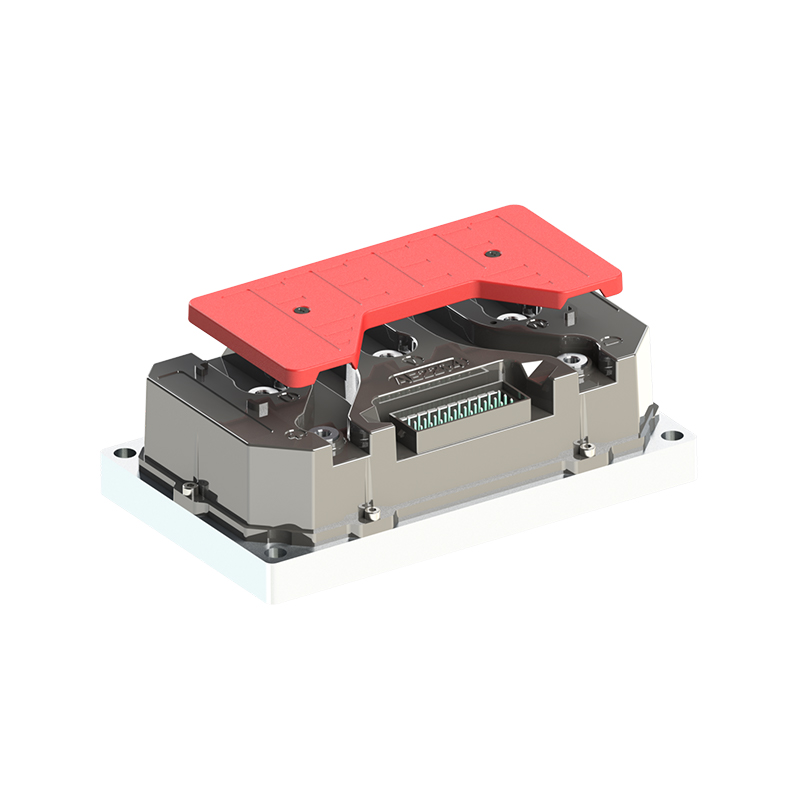

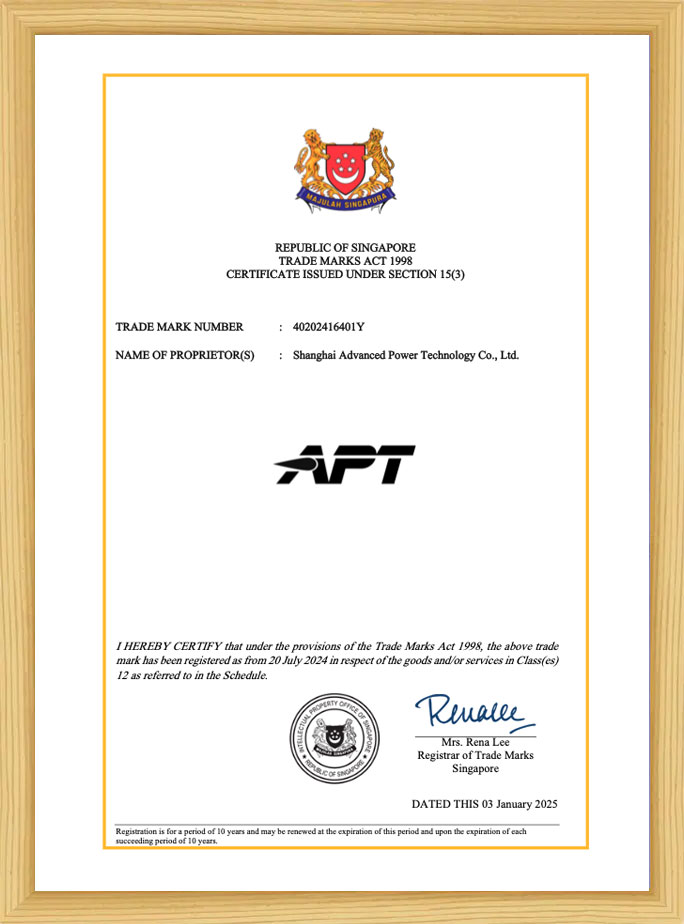

Controller for DC Brushless Motors are widely used in various applications due to their high efficiency, reliability, and long lifespan. Shanghai APT Power Technology Co., Ltd., founded in 2010, specializes in the development of advanced motor controllers, particularly for permanent magnet synchronous motors and brushless DC motors. Their expertise in motor control technology has enabled the company to provide high-performance solutions for the electrification of mobility vehicles. This section delves into the critical features of BLDC motor controllers and the innovations driving the industry forward.

Core Functions of a Brushless DC Motor Controller

Brushless Motor Drivers performs several essential functions to ensure smooth operation, efficient power conversion, and precise control over the motor's performance. Key functions include:

- Speed Regulation: The controller adjusts the speed of the motor based on input commands, ensuring consistent performance under varying load conditions.

- Torque Control: The controller regulates the torque output to maintain efficient operation and prevent overloading of the motor.

- Sensor Feedback Integration: BLDC controllers often use Hall sensors or sensorless algorithms to detect rotor position, providing critical feedback for commutation and control.

- Overload and Overheat Protection: Built-in protection mechanisms ensure that the motor and controller do not operate beyond safe limits, preventing damage to the system.

- Efficient Power Conversion: The controller uses pulse-width modulation (PWM) techniques to convert DC power to the AC power needed to drive the motor.

Designing BLDC motor controllers involves several challenges due to the complexity of these systems and the diverse applications they serve. Some of the most prominent challenges include:

- Complex Control Algorithms: Accurate speed and torque control requires sophisticated algorithms, such as vector control or direct torque control (DTC), which can increase system complexity and cost.

- Thermal Management: The controller and motor generate heat during operation, and managing this heat is crucial for maintaining optimal performance and longevity.

- Sensor Integration: While many BLDC motors use Hall sensors for feedback, implementing sensorless control algorithms can be more cost-effective and reliable for certain applications, but requires advanced control strategies.

- Noise and Vibration Minimization: High-frequency switching of the controller can lead to noise and vibrations, which must be minimized for applications like robotics and electric vehicles where smooth operation is essential.

- Efficiency at Low Speeds: At low speeds, BLDC motors often experience reduced efficiency. Developing controllers that maintain high efficiency across the full operating range remains a key area of focus.

Innovations in Brushless DC Motor Control

Several innovations in BLDC motor control technology have improved the performance and capabilities of these systems. Some of the key developments include:

- Wide-Bandgap Semiconductors: The use of SiC (silicon carbide) and GaN (gallium nitride) semiconductors in the motor controller enables higher efficiency, faster switching, and reduced heat generation.

- Advanced Sensorless Control: Innovations in sensorless algorithms allow for more accurate control without the need for physical sensors, reducing cost and improving reliability.

- Improved PWM Techniques: Enhanced PWM algorithms, such as space vector modulation (SVM), enable smoother motor operation, particularly at low speeds, and reduce power losses.

- Adaptive Control Strategies: Machine learning-based controllers can adjust to varying operating conditions, learning from real-time data to optimize performance and efficiency.

Applications of Brushless DC Motors and Controllers

Brushless DC motors and controllers are used in a wide variety of applications, from electric vehicles to industrial machinery and consumer electronics. Shanghai APT Power Technology Co., Ltd. plays a significant role in providing high-quality motor control solutions for these diverse sectors. Below are some of the most common applications:

Electric Vehicles

BLDC motors are commonly used in electric vehicles (EVs) due to their high efficiency, compact size, and excellent torque characteristics. The role of the motor controller in an EV is crucial for managing power distribution between the motor and the battery, ensuring smooth operation and extending battery life. Shanghai APT Power Technology Co., Ltd. supplies reliable brushless DC motor controllers that meet the high standards of the electric vehicle industry.

Consumer Electronics

Brushless DC motors are commonly used in devices such as fans, drones, and power tools. These applications benefit from the motor’s low maintenance requirements, high efficiency, and ability to operate in compact spaces. Controllers for these motors must ensure smooth and precise operation while maintaining power efficiency.

Industrial Automation

BLDC motors are widely used in industrial automation systems, including robotics and CNC machines, due to their precision and reliability. The motor controllers used in these applications must handle high-speed operation and precise positioning, making advanced feedback and control strategies essential.

Future Trends in Brushless DC Motor Control

As the demand for more efficient and reliable motor control systems increases, several future trends are shaping the development of BLDC motor controllers. These trends include:

- Integration with IoT: The integration of Internet of Things (IoT) capabilities in motor controllers will enable remote monitoring, predictive maintenance, and real-time performance optimization.

- Wireless Charging: Advances in wireless power transfer technology could eliminate the need for wired connections, making it easier to charge electric vehicles and other battery-powered devices.

- Energy Recovery Systems: Future controllers may incorporate advanced energy recovery techniques, improving overall system efficiency and reducing power consumption.

- Smart Algorithms and AI: The use of AI to adapt motor control strategies in real-time will lead to more intelligent systems capable of optimizing performance across various operating conditions.

English

English Español

Español عربى

عربى